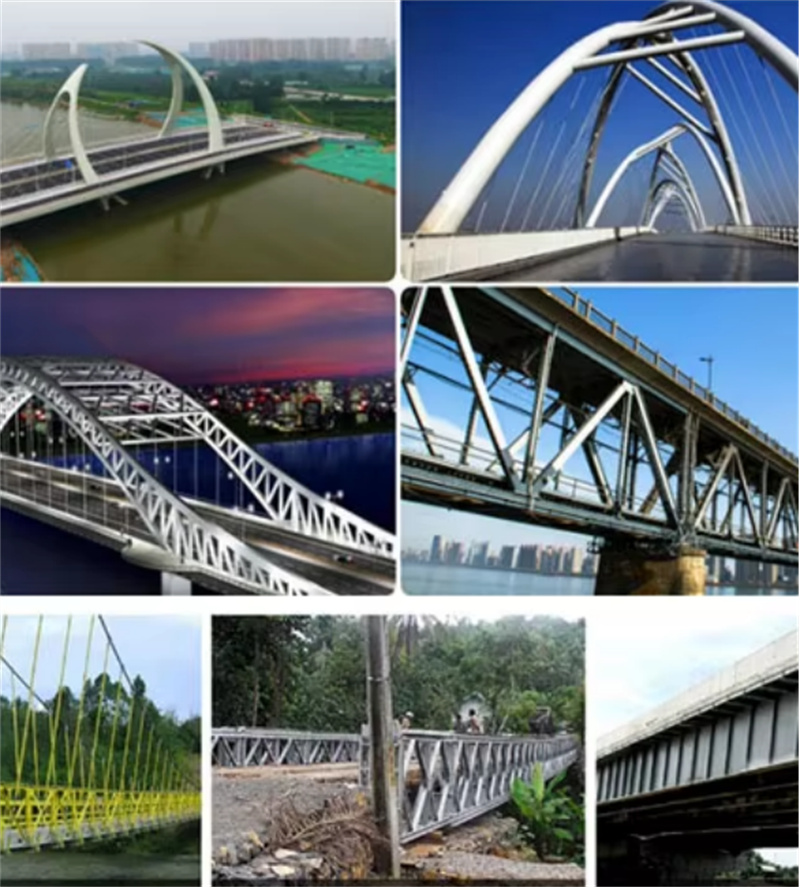

Steel Structure Suspension Bridge

Steel structure bridges refer to bridges whose main load-bearing structure uses structural steel. The beam and the leg or pier (pedestal) body form a rigid connection. Due to the consolidation of the pier and beam, the beam and pier are stressed. The pier not only bears the vertical pressure caused by the load on the beam but also the bending moment and horizontal thrust.

Classification of steel structure bridges:

1. Suspension bridge.

Suspension bridges are generally long-span with a theoretical maximum span of up to 4 kilometers. They are also one of the preferred types of bridges over a kilometer. The suspension bridge supports the upper part of the bridge through the main cable on the cable tower and the cables anchored on both banks.

The cable is the most essential load-bearing component. Due to the force balance condition, its shape forms a nearly parabolic cable shape from the middle to both banks. A suspension rod is hung from the cable to suspend the bridge deck, and stiffening beams are provided between the suspension rod and the bridge deck. Combining the two can effectively reduce the deflection deformation of the bridge caused by the load.

2. Cable-stayed bridge.

Also known as a cable-stayed bridge, its structure is relatively simple, mainly composed of stay cables, main beams, and cable towers. This bridge fixes all wires through the bridge tower and is connected to the beam body through the cables for pressure-bearing purposes.

In cable-stayed bridges, cables serve as multi-span elastically supported continuous beams instead of piers. This method of building a bridge can effectively reduce the internal bending moment of the beam and, at the same time, reduce the height of the building. The overall structure is lighter and consumes less material.

3. Arch steel structure bridge.

Arch steel bridge is also one of the most common steel structure bridges. Its load-bearing structure is mainly arch ribs, which bear axial force and have little or no bending moment. In the construction of steel arch bridges, the central arch is made of multiple steel pipes, and the cross beams and central arch can be hoisted and welded on site separately. This can effectively solve the problem of overweight one-time hoisting and greatly facilitate on-site construction. Shortening the construction period also plays an important role.